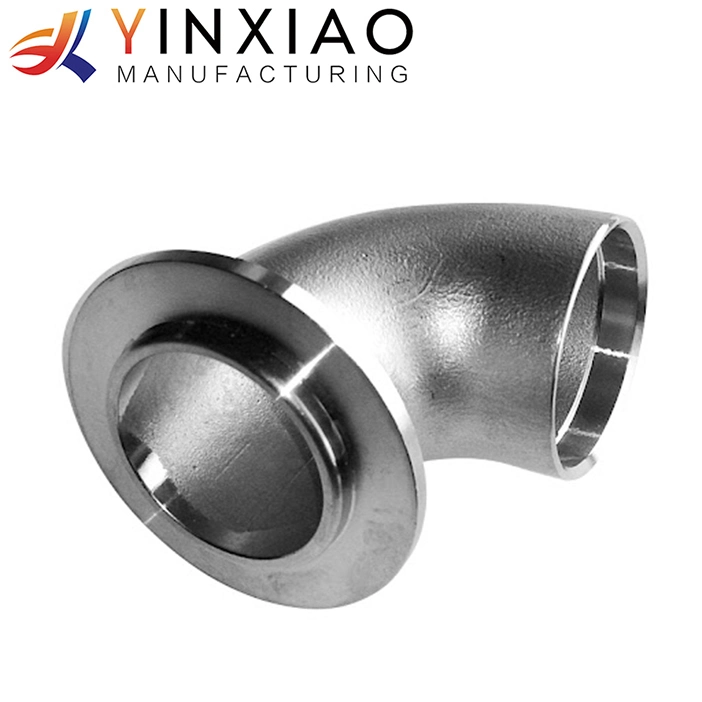

Aluminum Gravity Casting Zinc Aluminium Alloy Die Casting Parts with CNC Machining

Basic Info.

| Model NO. | YX-G001 |

| Material Inspection Report | Material Inspection Report |

| Dimension Report | Dimension Report |

| Standard | as Your Need |

| Certification | ISO 9001:2008 |

| Quality | High Level |

| Trade Assurance | Protect Your Order Everything |

| Item | Custom Homemade Metal Stamping Parts |

| Surface Finished | Sandblasting, Painting, Polishing, Poweder Coating |

| R&D | 3 Engineers for Electric Gold Plated Stamping Part |

| Sales Team | Response Within 24 Hours |

| Applied Software | PRO/E, Auto CAD, Solid Work, Caxa |

| Inspection | 100% Factory Inspection in House |

| OEM Experiences | 13years |

| Sample | for Free |

| Delivery | 15-20working Days |

| Experience | Since 2006 |

| Transport Package | Wooden Box/Cartons/as Your Need |

| Specification | OEM ODM parts |

| Trademark | YX |

| Origin | Shandong, China |

| HS Code | 73259990 |

| Production Capacity | According to The Customer′s Needs and Arrange The |

Product Description

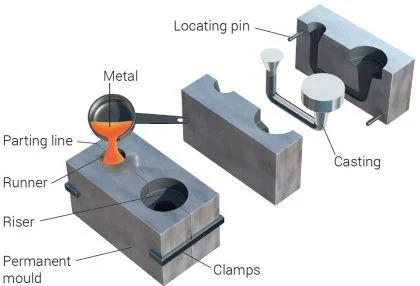

Product DescriptionWhat is Gravity Die Casting?Gravity Die Casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Undercuts, and cavities can be incorporated into the component form with the use of sand cores. This process gives a better surface finish than sand casting as well as better mechanical properties, both due to rapid solidification.

| Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM242) Zinc alloy 3#, 5#, 8# |

| Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

| Size | 1) According to customers' drawings2) According to customers' samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 |

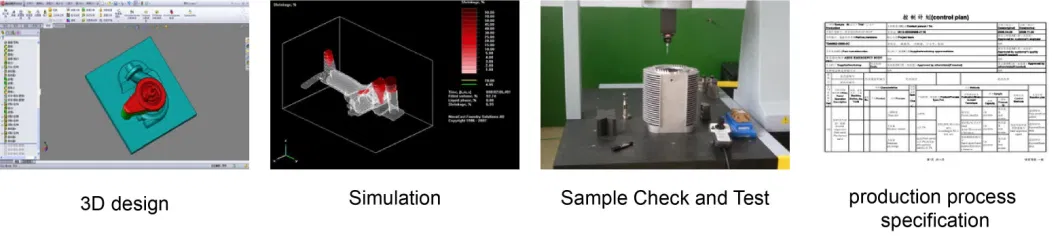

Yinxiao Manufacturing provides you with one-stop service from Raw materials → Precision Investment casting, Lost wax casting, Sand casting, Die casting, Centrifugal casting, Sheet metal Stamping → Rapid tooling → CNC Machining → Surface Treatment → Quality Inspection → Timely delivery to customersWHAT WE DO:* Casting parts (Steel, stainless steel, carbon steel, Iron, gray iron, ductile iron, Aluminum, aluminum alloy, Copper, brass, copper alloy, etc.);* CNC Machining (Machining Center, Turning, Milling, Planing, Grinding, Drilling, etc);* Sheet metal (Stamping, Laser Cutting, Bending, Welding);* Plastic injection (polystyrene (PS), polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polymethyl methacrylate (PMMA), etc.);* Surface treatment (sandblasting, shot blasting, painting, spraying, electrophoresis, anodizing, polishing, electroplating, etc.);

Our Advantages

Advantages and disadvantages:

- Excellent dimensional accuracy (dependent on casting material, but typically 0.1 mm for the first 2.5 cm (0.004 inch for the first inch) and 0.02 mm for each additional centimeter (0.002 inch for each additional inch).

- Smooth cast surfaces (Ra 1-2.5 micrometres or 0.04-0.10 thou rms).

- Thinner walls can be cast as compared to sand and permanent mold casting (approximately 0.75 mm or 0.030 in).

- Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces).

- Reduces or eliminates secondary machining operations.

- Rapid production rates.

- Casting tensile strength as high as 415 megapascals (60 ksi).

- Casting of low fluidity metals.

The main disadvantage to die casting is the very high capital cost. Both the casting equipment required and the dies and related components are very costly, as compared to most other casting processes. Therefore, to make die casting an economic process, a large production volume is needed. Other disadvantages are that the process is limited to high-fluidity metals, and casting weights must be between 30 grams (1 oz) and 10 kg (20 lb).[note 3][10] In the standard die casting process the final casting will have a small amount of porosity. This prevents any heat treating or welding, because the heat causes the gas in the pores to expand, which causes micro-cracks inside the part and exfoliation of the surface.[4] Thus a related disadvantage of die casting is that it is only for parts in which softness is acceptable. Parts needing hardening (through hardening or case hardening) and tempering are not cast in dies.

Our Service* One-Sotp service(from design to mass production)* OEM /ODM Customized services* Rapid prototyping & low-volume production* High quality & low prices* Highly skilled manufacturing process.* Strict quality Control System.

* Fast reactions and high efficacy Problems solving; * Have knowledge from part design, Quotation, Casting, CNC Machining to Finish; * Understand customer needs: product application, service environment, usage and so on; * Bring value to add we to customers and care about customer's business;

We are here, wish to be your friends.We promise that we can offer good quality&service on Casting CNC Machining, but for sure, more competitive price and better lead time.