Customized Precision Auto Hardware Machining Die Casting Aluminum Parts with Zinc Alloy Tools

Basic Info.

| Model NO. | die casting parts |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 1 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Secondary Process | Burring .Drilling .Threading |

| Type | Aluminum Die Casting |

| Process | Casting. Deburring .Drilling .Threading |

| Drawing | as Customer′s Required |

| Usage | Industrial Parts |

| Package | Customer′s Requirement |

| Finish | Ra1.6 |

| Quality Control | Professional Inspection |

| Weight Range | 0.005kg-50kg |

| Secondary Machining | Milling, Tapping, Grinding |

| Surface Finish | Anodizing, Polishing, Powder Coating etc |

| Technology | Die Casting |

| Strict QC | Reliable with Precision 0.02mm |

| Delivery | 30 Days After Payment |

| Tolerance | +/-0.1mm or as Drawings |

| Transport Package | Wooden Box |

| Specification | Custom size |

| Trademark | ZFC or OEM |

| Origin | China |

| HS Code | 7326901000 |

| Production Capacity | 100tons/Month |

Product Description

Customized Precision Auto hardware machining Die Casting Aluminum parts with Zinc Alloy toolsProduct Description

1. Aluminium die casting is a process of injection aluminum alloy under pressure, which produces parts in high volume at low costs.2. There are two processes of Aluminum die casting: hot chamber and cold chamber.3. A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.4. Qingdao Xinghe Machinery Company Limited ---we have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.5. Certification: TS16949, ISO9001, SGS, ROHS

| Name | High Pressure Aluminum Zinc Die Casting Parts |

| Material | ADC12, A380, A356, ADC10, Zinc Alloy Zamak |

| Dimension | Mini 20*20 mm, Max800*800 mm |

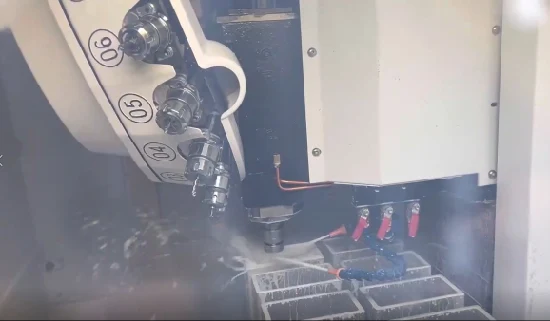

| Technology | High Preressure Die Casting, CNC, CMM Measure, Painting, X-Ray Detection |

| Processing | 1, Sign Drawing (General clients provide the drawing or samples)2, Opening the Mold3, Die Casting ( Aluminium or Aluminium Alloy)4, Precision Machining (Burring, Lathe, Milling, etc)5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing6, Inspection and Packing |

| Application | Automobile 42%, Furniture 21%, Industry 18%, Lighting 15%, Other 4% |

Detailed Photos

Aluminum Zinc die-casting products are characterized by high quality, light weight, high hardness and nice appearance.Therefore, aluminum die casting products are widely used in the automotive field. For example, Heat sink, Engine cooling fan, Water pump housing, end cover, air condition housing etc.

Company Profile

Since the founding of Zhong Fu Metal company investment casting, the company has identified the development strategy based on technology leading, market-oriented, innovation driven, talent centered and efficiency centered. Through the combination of technology innovation and industry university research, we will combine metallurgical technology with investment casting technology and digital information technology to develop digital, intelligent and flexible new Foundry Company.

Certifications

The company has been awarded "Qingdao Private Science and Technology Progress Company", "Heavy Contract and Credit-keeping Company", "Excellent Tax Company" and "Excellent Financial Contribution Company". And has passed the ISO 9001 certification, TS16949 auto parts certification and CE certification exported to Europe.

Our Advantages

1. Innovation & TechnologyWe are adopting the most efficient, and environmentally friendly technology to manufacture the best marine hardware for global customers. Our technology makes our products endure.2. Design & ManufactureAlways focus on the customer's demand for solid and pretty marine products. We design and manufacture products to meet today's modern style, to equip customers' boats with strong and delicate hardware. That's the principle for all of our technicians.3. Quality & ProductivityWe have set a scientific procedure for product's design, manufacture and test to ensure all products are of quality and beauty. With skilled technicians and efficient machines, we are able to produce in a large scale to meet the demand of wholesale partners.4. Trustable ServiceOur service starts from your enquiries, and last to your final satisfaction. We would help you settle every detail of your demand, choose your most favorable products and arrange most efficient shipment and handle all other procedures till the product fits your boat well.

FAQ

Q1. When will you send the products after the order is placed?Answer: Most of our products are available in stock, and we would arrange for delivery as soon as the order details are confirmed.Q2. Can you help arrange for shipping if in large quantity?Answer: Yes, we would provide one-stop service for all customers including manufacturing, package, shipping and after-sales service. We could provide most efficient shipping service as required.Q3. How can I pay the order ?Answer: We have several payment tools available to customers, please confirm with our salesman before your payment to ensure the payment is safe and efficient.Q4. Can you customize my products?Answer: Yes, we have factories and could design and manufacture products with specific requirement. Please do not hesitate to contact us and tell us your demand.