Design Your 3D Printing Insert Mold Parts for Conformal Cooling

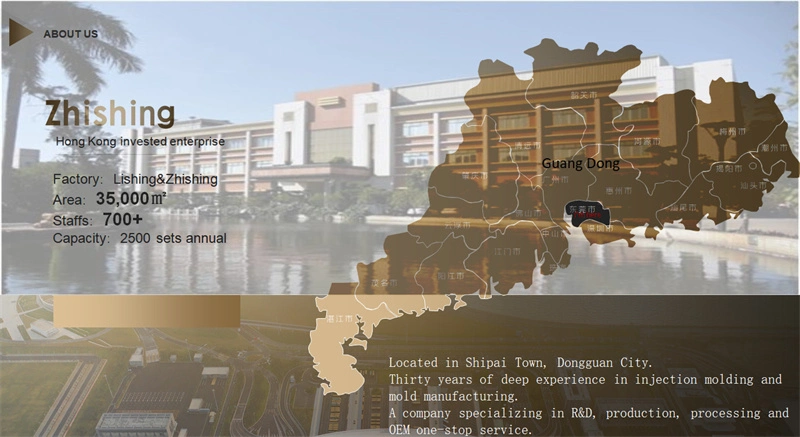

Our Staffs: Mould Trade Process: FAQ: Q: Are you a factory or trading company?A: We are a professional manufacturer of i

Basic Info.

| Model NO. | ZSM-6213 |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 24hrs Online Service |

| Transport Package | Plastic Film+Wooden Case |

| Specification | Custom |

| Trademark | Zhishing |

| Origin | Guangdong Dongguan |

| HS Code | 8480719090 |

| Production Capacity | 2000 Sets/Year |

Product Description

| Plastic Injection Mold | |||||||||

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, MA,PVC,TPE,TPU etc | ||||||||

| Material of Steel | 738,718,NAK80,S136,P20 etc | ||||||||

| Surface Requirement | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing | ||||||||

| Tolerance Request | UP to (±0.005mm) | ||||||||

| Mould Life | 500000-1200000 shoots | ||||||||

| Multi Injection | Single/Double/multi color | ||||||||

| Design Software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad | ||||||||

| Injection System | Hot /Cold Runner | ||||||||

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required | ||||||||

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc | ||||||||

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc | ||||||||

| Ejector System | Stripper plate,Lifter,Push bar,Ejection pin etc | ||||||||

| Steel Standard | FINKL,Assab,DAIDO,LKM,Buderus | ||||||||

| Cooling | Baffles/Sprin Piple/3D printing water line | ||||||||

| Standard Parts/Cylinders | DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle | ||||||||

| Design Capability | DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea | ||||||||

| Documents / Reports Provided | Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report | ||||||||

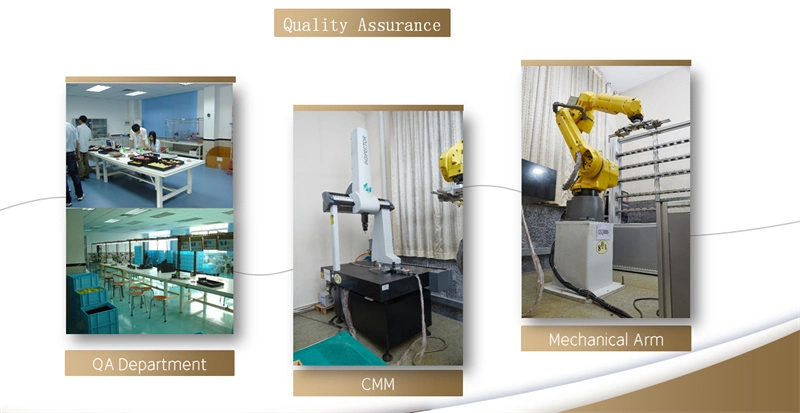

| Certificate | ISO9001 ISO14001 | ||||||||

| MOQ | 1sets | ||||||||

| Lead Time | 6-10 weeks or according to the order requirement | ||||||||

| Payment | 40%Deposit, 30%Before Product Inspection, 30%Before Shipment | ||||||||

| Port of loading | SHUNDE/GUANGZHOU/SHENZHEN | ||||||||

| Cooperate with the relevant vocational and technical colleges to help their graduated students provide them internship job, during then select those who's ability is excellent(20 out of 100 people), to ensure that the technology is passed on, and the new blood in creativity. |

Mould Trade Process: FAQ:

Q: Are you a factory or trading company?

A: We are a professional manufacturer of injection mold for above 30 years in Donguan China

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs

Q: My products have already been developed on CAD. Can you use the drawings?

A: Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

| Back to Home to Know MoreContact |

Send to us