Inconel 625 Gh3625 3D Printing Premium Titanium Alloy Turbine Billet Turbocharger Compressor Impeller Wheel Parts

Win the future OBT: Win the future OBT: Founded in 2003, OBT has been a leading manufacturer and exporter in the precisi

Basic Info.

| Model NO. | OBT |

| Surface Roughness | Ra 0.8-Ra3.2 According to Customer Requirement |

| Machining Tolerance | +/-0.01mm |

| Standard | ASTM |

| Certification | CE, ISO 9001:2000, ISO 9001:2008 |

| Service | Custom Carbon Steel Water Pump Impeller |

| Transport Package | Packed with Free Fumigating Wooden Case |

| Specification | Customize |

| Trademark | OBT |

| Origin | Shandong, China |

| Production Capacity | 100000 Piece/Pieces Per Month |

Product Description

Win the future OBT:

Win the future OBT: Founded in 2003, OBT has been a leading manufacturer and exporter in the precision casting industry for 20 years, adhering to the corporate philosophy of excellent quality, reasonable price and perfect after-sales service, relying on superb research and development and German manufacturing technology . Our OBT provides our customers with the safest non-standard customized investment casting products and helps them develop the market. Products include: turbocharger accessories such as impellers and impeller blades, precision casting accessories, and other hardware accessories. OBT has passed ISO9001, ISO14001, CE, EAC, TUV, SGS, SABER, TS16949, CE, EAC, SGS safety certification, and provides our best products and services successfully sold to America, Europe (France, UK, Germany, Sweden , Hungary, CE, Czech Republic, Russia, Ukraine, Italy, Poland, etc.) South America, Southeast Asia, Australia, Africa and other more than 40 countries and markets, and won unanimous praise from a wide range of customers. We have expanded the world market to more than 382 customers, including distributors and end-user customers.In the future, Oberthur Group will continue to uphold the people-oriented and customer-oriented business philosophy, make persistent efforts to strengthen product development, give full play to the group's advantages, and explore the international market with the latest technology and perfect quality. Vigorously develop the market and provide customers with one-stop comprehensive solutions.

1.Product Description

| Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Superalloy | |

| Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc. | |

| Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |

| Steel Alloy:Carbon Steel / Die Steel / etc. | |

| Titanium Alloy: Grade 1/Grade 2/Grade 2 H/Grade 3/Grade 5/etc. | |

| We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Process | Lost wax casting + cnc machining |

| Casting dimension tolerance | ±0.01mm |

| Casting surface roughness | Ra 12.5um |

| Casting weight range | 0.1-90kg |

| Casting Size | Max linear size: 1200mm, Max diameter size: 600mm |

| Machining Precision | Positioning accuracy 0.008mm, Rep. position. accuracy 0.006mm |

| Machining surface roughness | Ra0.8~6.3um |

| Max Travel Of Spindle | 1800mmx850mmx700mm |

| Max Turning Diameter | 1000mm |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR....... |

| Surface treatment | KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powdercoating, Nickel plating |

| Service available | OEM & ODM |

| Quality control | 0 defects,100% inspection before packing |

2.Major Machining Equipment List:

| Machining Capabilities | |

| Three-Axis turning centre: 1 | Four-Axis Vertical Machine Center: 20 |

| Four-Axis Horizontal Machine Center: 1 | CNC Milling Machine: 6 |

| Vertical Lifting Milling Machine: 4 | Universal Milling Machine: 2 |

| Plane Milling Machine: 2 | Fase Milling Machine: 3 |

| CNC Lathe Machine: 21 | Oblique Guide CNC Lathe Machine: 2 |

| Engine Lathe Machine: 6 | Special Lathe: 5 |

| Radial Drilling Machine: 4 | CNC Porous Drilling Machine: 6 |

| CNC Spcial Drilling Machine: 2 | Cylindrical Drilling Machine: 11 |

3.Casting Products 4.Product Advantages 5.Inspection Tools 6.Lost Wax Casting Process

7.Packing & Delivery

Standard packing: pearl cotton/bubble bag + carton box + pallet/wooden box

Special packing: custom packaging + wooden box

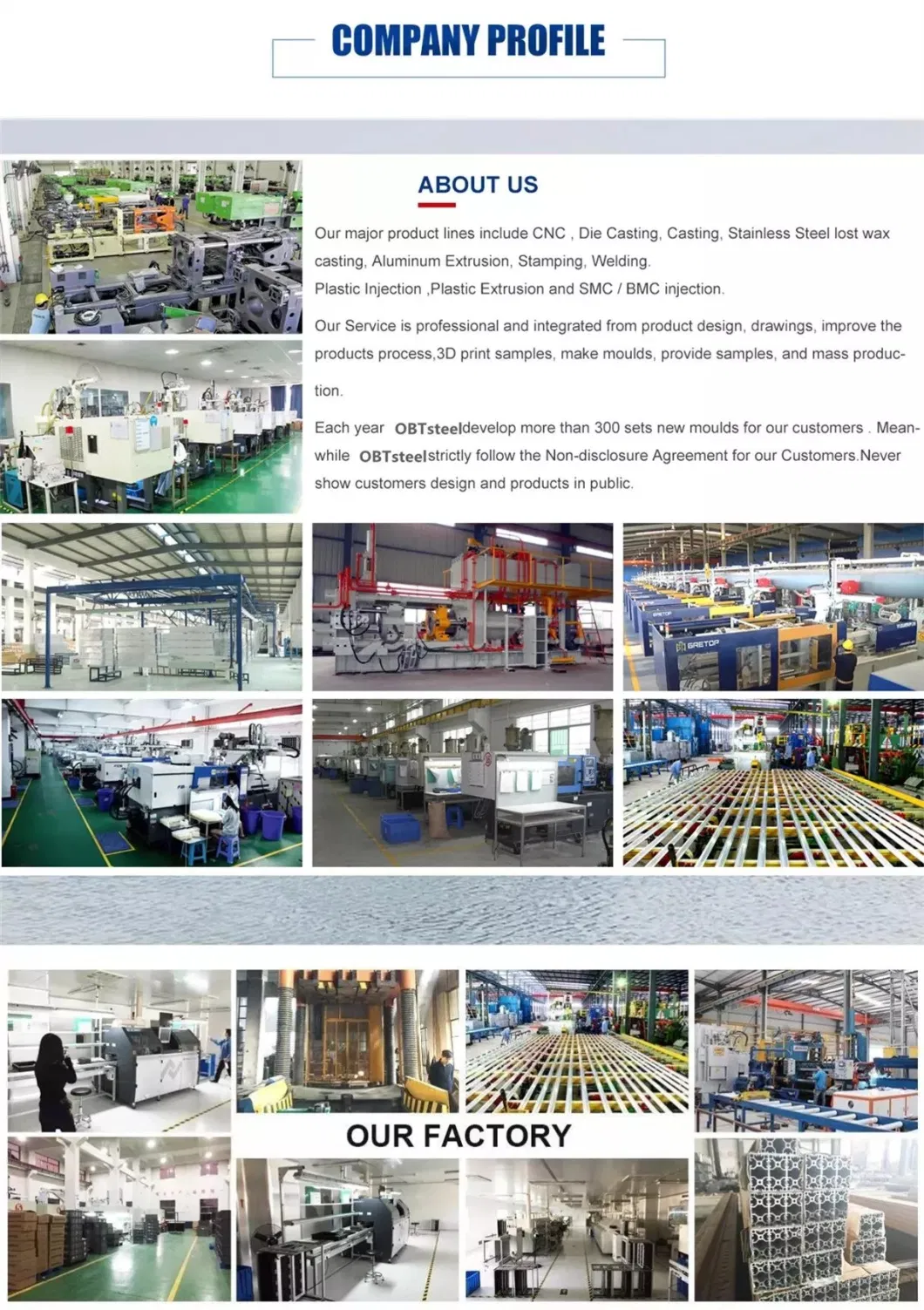

8.Company Profile

9.FAQ

1.Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years' export experience for designing and producing metal castings.

2. What kind of production service do you provide?

Mold making, lost wax casting, CNC machining, stamping, plastic injection, assembly, and surface treatment.

3.What do I need for offering a quote ?

Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.), quantity, applicationor samples. Then we will quote the best price within 24h.

4.What materials you can do?

We make investment castings of stainless steel, carbon steel, aluminum, brass or bronze.

5.What is the production cycle?

It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement by adjusting ourworkshop schedule.

10.Related Products

Send to us