Sample Customization ABS Custom Plastic Electronic Device Housing Injection Molding Part

Package Size 60.00cm * 50.00cm * 46.00cm Package Gross Weight 0.040kg Sample Customization ABS Custom Plastic Electronic

Basic Info.

| Model NO. | injection molding part |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Available |

| Type | Injection Molding Part |

| MOQ | 10 |

| Quality Control | 100% Inspection Before Shipping |

| Color | Customized |

| Transport Package | Customized |

| Specification | customized |

| Trademark | YANYANG |

| Origin | China |

| Production Capacity | 500000PCS/Month |

Packaging & Delivery

Package Size 60.00cm * 50.00cm * 46.00cm Package Gross Weight 0.040kgProduct Description

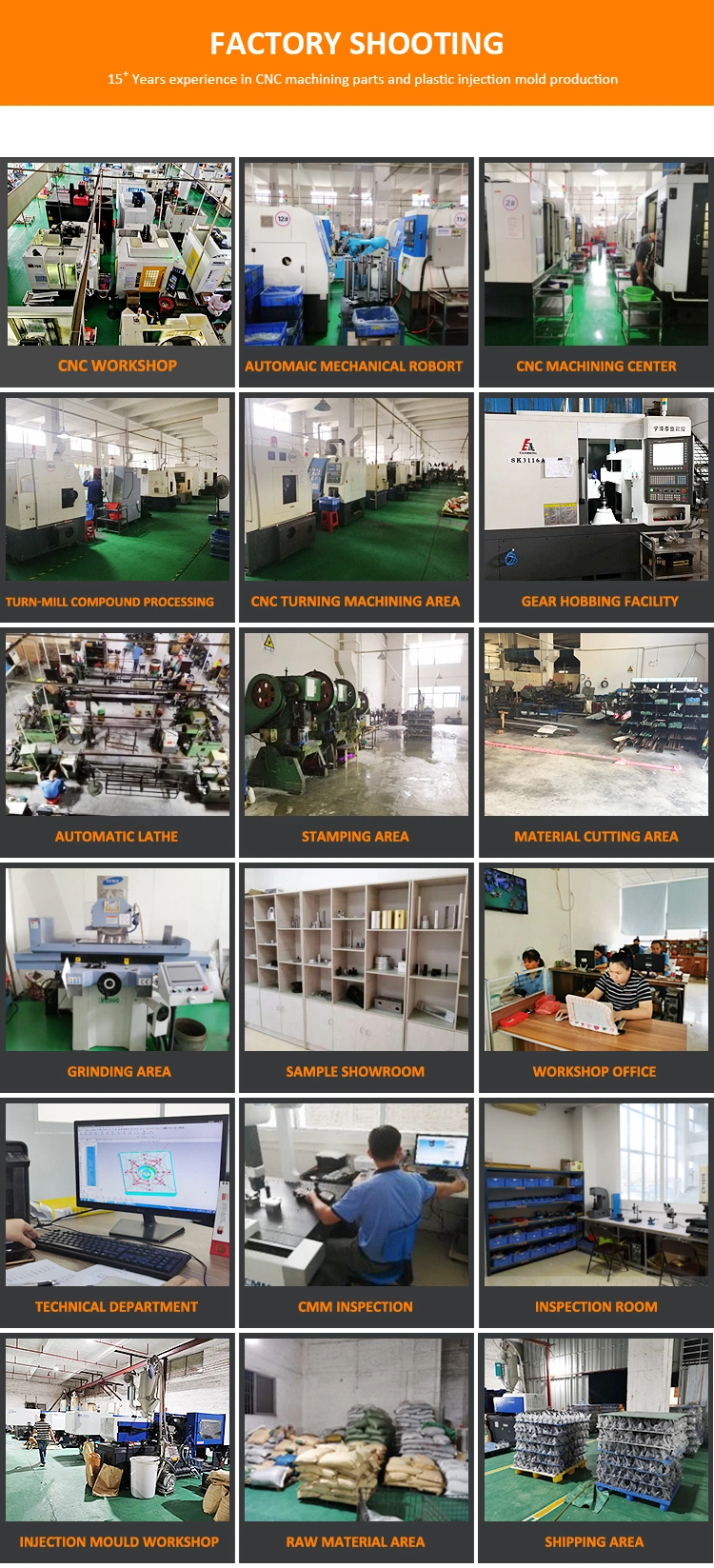

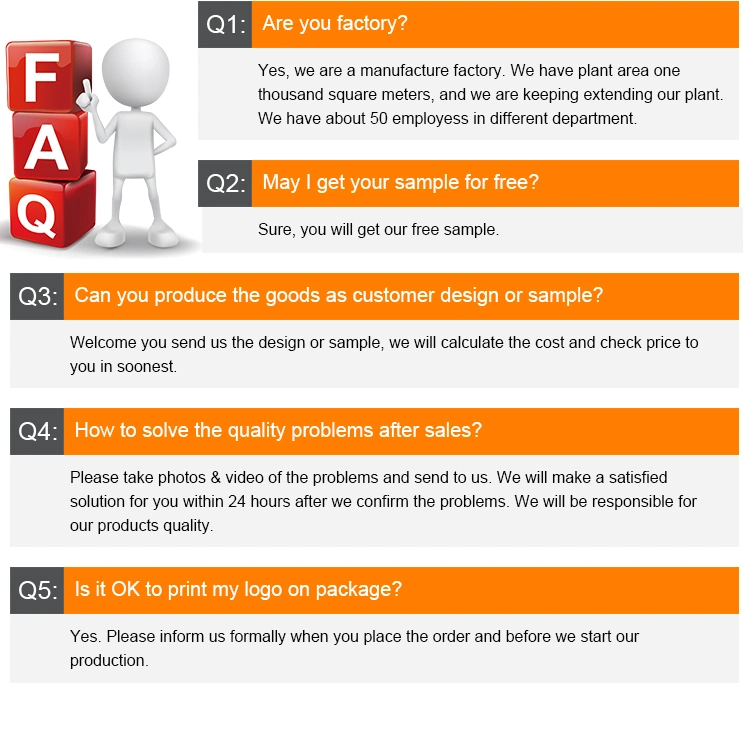

Sample Customization ABS Custom Plastic Electronic Device Housing Injection Molding Part1. 100% inspection before delivery;2. High performance of CVD/PVD coating, with super hard and smooth surface;3. ISO9001:2015 quality system control;4. Customized size and spec /OEM.ODM available ;5. Precise dimension, high accuracy;6. 15+ years experienced engineers team and well trained sales team to support every project.;

| Mould material | ABS, PE, PVC, PA6, PET,etc. |

| Hardness of steel | Vacuum quenching, nitride, hrc41-47, hrc46-50, hrc60 |

| Mould base | LKM, HASCO |

| Mould cavity | Single / Multi |

| Runner system | Hot / Cold |

| MoInjection machies equipments | According to product precision to choice the different model 100T,128T,150T,200T,250T,368T,450T injection machine. |

| Inspection | 100% inspection by QC, QA before shipping. |

| Fast mould design | Can be within 1-3 working days after getting customer's drawings |

| Lead time | Plastic moulds : 3- 6 weeks after getting the mould design confirmation |

| Mould testing | All of the moulds can be well tested before the shipments. Videos for moulds trial running are available. |

| Minimum order | Small orders for injection moulding can be accepted |

| Production capacity | 50 sets/month |

| CAD for quote | Step.& dwg. |

| Mould life | 100-500K shots |

| After sales service | Available by our staff with more than 10 years of working experience in this field |

Send to us